The metal working of an auto body depends highly on sheet metal service. What car do you own? It might be a racing car with a flat-sided auto body or a family car. In both cases, you have to face metal working specifically on sheet metal functions. The bending and shaping of sheet metal and restoring them into useful car parts will be the center of today’s topic.

Like many automotive works, sheet metal is also easy to start but complicated to finish smoothly. Maximum sheet metal job can be accomplished without heating process lie welding. To get good results, you can normally accept a sheet metal project with some benchtop brake and a few aircraft shears. The professional output is different though you can become confident enough to our guidelines.

Hang on! and allow us an opportunity to go deep down into your confusion and solve it accordingly.

The functions of sheet metal for auto body repair

A lot of metal finishing and bumping work is to be executed before gauge sheet metal. The perfect size for automotive sheet metal is between 18 to 20 gauge. 20 gauge is the most used gauge sheet metal for automotive functions. The abundant metal will be 0.0478 to 0.0359 inches and still need to be cautious about the bumper and metal finish.

Aluminum is preferable in sheet metal fabricators for the dashboard panels. Make sure it is a lightweight material so that you can easily move it. You must know what type of restoration you are planning for your vehicles. Once you are aware of the customized functions and relevant subjects of your car for sheet metal working, you know how to do and what to do specifically.

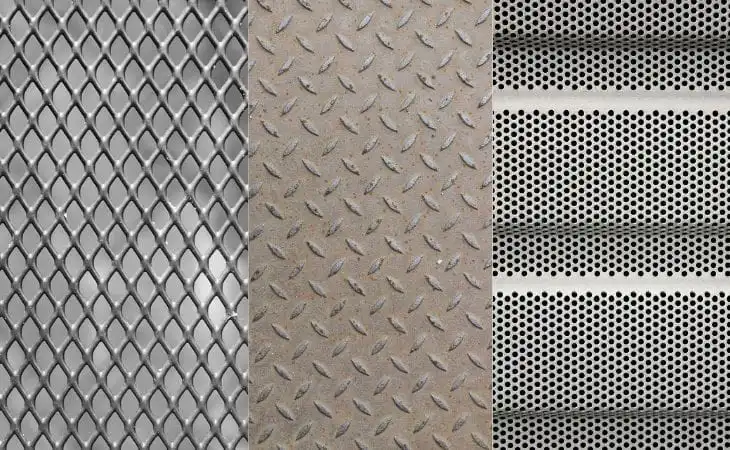

There are fundamentally three different forms of sheet metal that are sold in the market.

- Mild steel

- Aluminum

- Stainless steel

Mild steel

Mild steel is a brilliant item to use for fenders, doors, and firewalls. Most of the car parts are trusted with this form of sheet metal. For those who want light sheet metal as we mentioned to choose it, mild steel will be ideal for them. Affordability is one of the most amazing parts of mild steel surprisingly. You can bend and twist it into several different shapes since it is extremely flexible. Avoid heating procedure for the mild steel as it may be impactful to the carbon content.

Aluminum

A lightweight and easily tolerable option among the sheet metal forms is aluminum. It is suitable for the dashboards due to its relativity attitude. Because of its recycling benefits, many natures lover wants it over steel. Moreover, it is actually stronger than normal steel. Though mild steel is more affordable than this, aluminum also comes at a very reasonable price.

Stainless steel

Stainless steel acts as a compound of iron, chromium, nickel, and various metals. The durability is praiseworthy as it is extremely resistant to corrosion. Brackets, tubing, panels for the car parts section are popular in stainless steel because of their nature. It is slightly expensive and gets dirty soon. Except for these two, stainless steel is a combination of potency.

You must acquire knowledge about the pros and cons of different sheet metals and check their adjustability on your particular machine. Do not stay in confusion while selecting sheet metal for your auto body. If possible, consult with nearby professionals and consider their recommendations based on your budget.

What gauge metal is used for auto repair?

Normally 18-gauge sheet metal is used for body panels. Mild steel gets priority here and some racers choose 20-gauge sheet metal over 18 gauge. Then they start working to lighten mechanisms up. We recommend staying away from blends, if possible, at all.

Best sheet metal for auto body repair

Mild steel is the most using sheet metal that contains extreme material. Mild steel seems appropriate for firewalls, door skins, and fenders. The lightweight function of mild steel makes this ideal for consumers.

The average size of a gauge metal in the car

Maximum cars are constructed with a 0.7 mm metal steel sheet. The car frame usually contains 18 gauge and sometimes 20 gauge. As we mentioned earlier, the factual depends on the customer requirements. 11 gauge is the most standard size of gauge steel in a car frame though many C-channels frames are used to 7 gauge on one side.

The ethnicity of sheet metal for fixing a car

Well, that depends on the classical features of the car. If it is a 1957 car, you need to follow a particular instruction. If it is a new model, you can use effective steel for fixing it.

Here’s how do you measure the gauge metal

- Find the thickness through a tape

- Multiply the figure of millimeters by 0.03937 for converting to inches.

- Make sure that the thickness is accurate based on the sheet metal size of a particular piece.

The fundamentals of sheet metal work in auto body repair

Usually, there are two realms in which sheet metal work falls. One is manual arts and the other is technical skills. There is no single right approach for such a difficult task. You can go with various approaches that may produce effective results equally. Sometimes misdeeds occur in such a way that hides real damage and it takes to longer damage eventually. Therefore, be clear about what you are doing to your auto body parts.

Conclusion

After learning vital technical factors in automotive functionalities, you must know the consequences of various terms. It’s better to have experience in the related field to ensure efficiency. No matter if you do not have any because everything has a beginning.

There are many quotes available for the automotive sheet metal and particular gauge description. It will help you with the refinishing and restoration of your favorite car gently. Whatever you do, do it with a passion to execute the job properly that brings a good result ultimately.

You can also read Best Paint for Dashboard: Reviews & Buyer’s Guide 2022